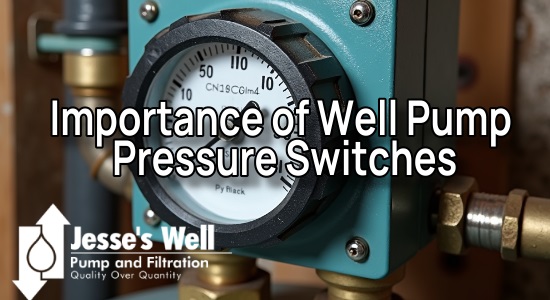

Importance of well pump pressure switches

11/15/2025

The Importance of Well Pump Pressure Switches

The well pump pressure switch is one of those small parts that quietly run your home, and then suddenly becomes the single thing between a steady water supply and a dry kitchen sink. If you own a well there is a good chance you have not thought much about the pressure switch until water pressure drops or the pump will not shut off. This article walks through why the well pump pressure switch matters, how a pressure switch works, common signs it needs service, safe troubleshooting you can do, and when pressure switch replacement is the right call.

What the well pump pressure switch does

The pressure switch is a mechanical device that senses water pressure in the tank and powers the pump when pressure falls below a set point. When pressure reaches the cut off setting the pressure switch opens and the pump stops. In practice, that means the pressure switch controls when the pump turns on and off, ensuring steady household water pressure and protecting the pump from short cycling.

How a pressure switch works in plain terms

Think of the pressure switch like a light switch that responds to pressure instead of a hand. Inside the switch, a small diaphragm or bellows senses pressure changes. As pressure drops the switch closes an electrical contact and the pump runs. As pressure rises, the contact opens, and the pump stops. Simple mechanism, but if the contact wears or the setting drifts, you get pump problems fast.

Common signs your pressure switch needs attention

- Irregular water pressure that jumps up and down rather than staying steady

- The pump runs much longer than it used to before shutting off

- The pump short cycles, meaning it turns on and off quickly and repeatedly

- The pump will not start even though the pressure is low in the system

- Visible corrosion or water around the switch enclosure

Any of those signs can point to a failing pressure switch, a waterlogged pressure tank, or electrical or wiring issues. It helps to rule out the pressure tank first because a waterlogged tank can mimic switch failure.

Simple checks you can do safely.

Before you call for pressure switch replacement it is reasonable to do a couple of safe checks. First, cut power to the pump at the breaker. Always verify power is off with a non-contact tester if you have one. Look for evident corrosion or a broken terminal on the pressure switch. If the switch has an access cover, you can inspect the contacts, but do not touch live parts. Replacing the cover and restoring power can sometimes reveal whether the switch closes when pressure drops.

When adjustment helps and when it does not

Pressure switches have two nuts that set cut in and cut out. Adjusting those nuts moves the on and off pressure slightly. Adjustment can correct small drift but it will not fix worn contacts or a failing internal diaphragm. If you adjust the pressure switch you must do so carefully and only after confirming the pressure tank is functioning. Improper adjustment can overwork the pump and reduce equipment life.

Why pressure switch replacement is common

Pressure switches are mechanical and exposed to moisture and electrical arcing at the contacts. Over time the contacts pit and the switch starts to behave unpredictably. Replacing the pressure switch is often cheaper and more reliable than repeatedly adjusting a worn part. A new pressure switch restores reliable on and off control and reduces the chance of pump short cycling.

Choosing the right replacement and safety reminders

When replacing a pressure switch, choose a model that matches your pump voltage and has the appropriate pressure range for your system. Typical home systems use thirty to fifty pounds per square inch settings but confirm the range that worked for your system before swapping parts. If you are not comfortable with electrical work hire a licensed pump technician. Working on pump electrical circuits can be dangerous and incorrect wiring can damage equipment.

Signs you should call a professional

- Any time you are uncomfortable working with electrical wiring

- Repeated pump short cycling after adjustment

- Visible burning or arcing inside the pressure switch box

- Persistent low pressure after checking the tank and switch

Professionals will test the switch under load, check the pressure tank bladder or air charge, and confirm wiring and pump protection are correct. They can recommend pressure-switch replacement or tank service during a single visit, if needed.

Small maintenance steps that extend the life of a pressure switch

- Keep the switch box tight and weather-protected

- Inspect the switch for corrosion annually

- Check the pressure tank air charge and correct it if needed

- Have the system tested by a professional every few years

These small steps reduce moisture in the switch and prevent early contact wear. In my experience regular check ups are what keep a household well system running years longer than neglect.

Final thoughts

The well pump pressure switch is a low attention part that plays a big role. If you understand how a pressure switch works and what to watch for you can avoid surprises, reduce repair costs, and keep steady water pressure. When in doubt call a qualified pump tech for pressure switch replacement or system diagnosis. A short fix now can save you the headache of a failing pump later.